Wholesale Smooth Coated Gloves: Waterproof, Wear Resistant

The Indispensable Role of Advanced Industrial Gloves in Modern Safety

In today's dynamic industrial landscape, worker safety is not merely a regulation but a fundamental commitment that drives operational excellence and fosters a productive environment. Personal Protective Equipment (PPE) stands at the forefront of this commitment, with industrial gloves playing a critical role in safeguarding hands from a myriad of hazards. Among the most innovative solutions emerging in the market are Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant. These gloves are engineered to offer a superior blend of protection, comfort, and durability, addressing the complex demands of various high-risk sectors.

This comprehensive guide delves into the specifics of these advanced industrial gloves, exploring their technical parameters, the intricate manufacturing processes, and their profound impact across diverse application scenarios. We will dissect the elements that contribute to their efficacy, discuss industry best practices, and provide insights into their economic and safety benefits, ensuring a holistic understanding of their value proposition.

Current Industry Trends and Market Demands for Industrial Gloves

The global industrial glove market is experiencing robust growth, driven by increasing awareness regarding occupational health and safety, stringent regulatory frameworks, and technological advancements in material science. Recent market analyses indicate a compound annual growth rate (CAGR) of approximately 6-8% for the industrial protective gloves segment, projected over the next five to seven years. This growth is largely fueled by the rising demand for specialized gloves that offer multi-functional protection against chemical, mechanical, thermal, and biological hazards. Key trends influencing this sector include:

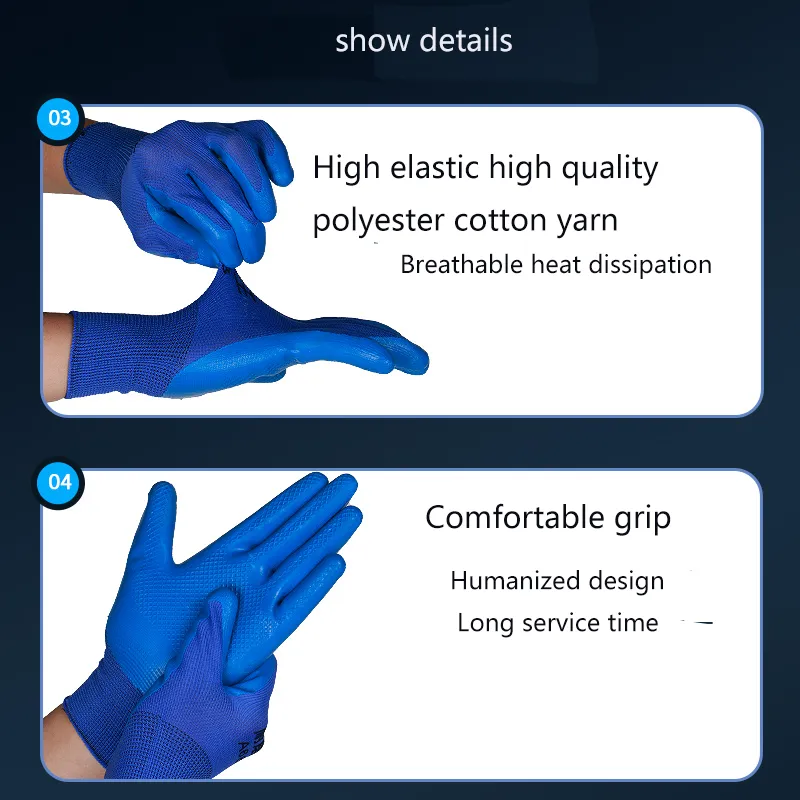

- Increased Focus on Ergonomics and Comfort: Beyond basic protection, workers demand gloves that offer dexterity, flexibility, and breathability, reducing hand fatigue and encouraging consistent use.

- Demand for Multi-Hazard Protection: Industries increasingly require gloves that protect against a combination of risks, such as cuts, abrasions, punctures, and chemical exposure, alongside waterproof capabilities.

- Sustainable and Eco-Friendly Materials: Growing environmental consciousness is prompting manufacturers to explore sustainable raw materials and eco-friendly production processes.

- Smart Gloves Integration: While still nascent, the development of smart gloves with integrated sensors for vital signs monitoring or hazard detection represents a futuristic trend.

- Stringent Regulatory Compliance: Evolving international safety standards (e.g., EN 388, EN ISO 374, ANSI/ISEA 105) necessitate higher performance levels and more rigorous testing for industrial gloves.

The Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant are perfectly positioned within these trends, offering high performance, comfort, and adherence to critical safety standards, making them a preferred choice for demanding industrial applications.

Technical Parameters and Product Specifications

Understanding the core technical specifications of Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant is crucial for assessing their suitability for specific tasks. These gloves are designed with precision, integrating advanced materials and innovative coating technologies to deliver superior performance. Key parameters include material composition, coating type, thickness, and various performance ratings based on international standards.

Material Composition:

- Liner Material: Typically high-performance knitted fabrics such as Nylon, Polyester, HPPE (High Performance Polyethylene), or a blend. These materials provide a comfortable fit, breathability, and varying degrees of cut resistance, forming the base structure of the glove. For instance, HPPE offers exceptional cut resistance for its weight, making it ideal for tasks involving sharp objects.

- Coating Material: The smooth coating is generally made from advanced polymers like Nitrile Butadiene Rubber (NBR), Polyurethane (PU), or Latex.

- Nitrile: Known for its excellent resistance to oils, fuels, and many chemicals, as well as superior puncture and abrasion resistance. Nitrile coatings offer a good balance of durability and tactile sensitivity.

- Polyurethane (PU): Provides good abrasion resistance, elasticity, and a thin, flexible coating that enhances dexterity, making it suitable for precision work. PU is also breathable and often preferred for dry environments or light oil applications.

- Latex: Offers superior elasticity, grip, and tactile sensitivity. While excellent for wet and dry grip, some users may have latex allergies.

Key Performance Indicators & Standards:

Our Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant adhere to stringent international safety standards, ensuring their reliability and protective capabilities. The primary standards include:

- EN 388:2016 + A1:2018 (Protection against Mechanical Risks): This standard rates gloves based on four performance levels:

- Abrasion Resistance (0-4): Measures how well the material resists wear from rubbing.

- Cut Resistance (0-X, where X indicates newton force for cut resistance; A-F for TDM-150 test): Measures resistance to cutting by a sharp object. For these gloves, a rating of C or D is often targeted for general industrial use, indicating good cut protection.

- Tear Resistance (0-4): Measures resistance to tearing when stretched.

- Puncture Resistance (0-4): Measures resistance to penetration by a pointed object.

- Impact Protection (P - optional): Indicates if the glove offers protection against impact (e.g., knuckles).

- EN ISO 374-1:2016 / EN ISO 374-5:2016 (Protection against Hazardous Chemicals and Micro-organisms): While primarily focusing on mechanical resistance and waterproofness, some variants of these smooth-coated gloves may offer basic chemical splash protection, indicated by permeation times for specific chemicals. The "Waterproof" aspect often relates to the integrity of the coating against liquid penetration.

- ANSI/ISEA 105 (American National Standard for Hand Protection Classification): Similar to EN 388 but for the North American market, classifying gloves for cut, abrasion, puncture, and chemical resistance.

Product Specification Table:

Below is a typical specification overview for Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant, showcasing the technical depth:

| Feature | Specification Details | Standard/Rating (Example) |

|---|---|---|

| Product Name | Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant | N/A |

| Liner Material | 13-gauge Seamless Knit Nylon/Polyester/HPPE Blend | Comfort & Dexterity |

| Coating Material | Smooth Nitrile/PU/Latex (Full/Palm Coated) | Enhanced Grip & Durability |

| Coating Type | Smooth, Waterproof, Wear-Resistant | Prevents Liquid Penetration, Longevity |

| Thickness | 0.8 mm - 1.2 mm (Coating Dependent) | Balance of Protection & Dexterity |

| Sizes Available | XS, S, M, L, XL, XXL (6-11) | Universal Fit |

| Color Options | Grey/Black/Blue (Customizable) | Visibility & Branding |

| EN 388:2016 Rating | 4131X, 4X42D (Example) | Abrasion: 4, Cut: X/D, Tear: 3/4, Puncture: 1/2, Impact: X |

| Waterproof Level | Full Coating ensures liquid impermeability | Hydrostatic Pressure Test (e.g., 200cm H2O) |

| Chemical Resistance | Basic splash resistance for oils, greases, some solvents | EN ISO 374-1:2016 (Type C for minor splashes) |

| Durability/Lifespan | Designed for extended use in demanding environments | Cycles of use (e.g., 20,000+ abrasion cycles) |

| Applications | General Assembly, Logistics, Construction, Automotive, Maintenance, Oil & Gas | Versatile Protection |

Detailed Manufacturing Process of Smooth Coated Industrial Gloves

The creation of Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant is a sophisticated process that combines textile manufacturing with advanced polymer chemistry and precise quality control. The manufacturing journey ensures that each glove meets the stringent performance requirements for protection, durability, and comfort. Below is a detailed breakdown of the key stages:

Process Flow Explanation:

-

Stage 1: Yarn Preparation & Knitting (Liner Creation)

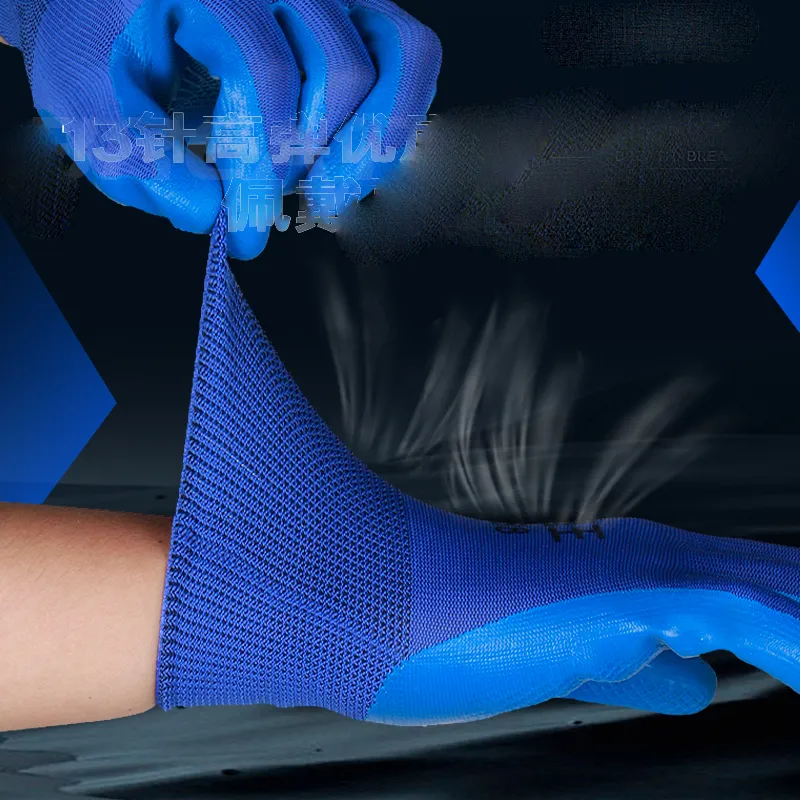

Description: High-quality synthetic yarns (e.g., nylon, polyester, HPPE, spandex) are selected based on desired properties like comfort, flexibility, and initial mechanical resistance. These yarns are then fed into advanced automatic knitting machines (e.g., 13-gauge, 15-gauge, or 18-gauge) to create seamless glove liners. The gauge refers to the number of stitches per inch, influencing the liner's thickness and dexterity. Finer gauges (higher numbers) result in thinner, more dexterous gloves.

YARN SELECTION & PREPARATION → SEAMLESS KNITTING

-

Stage 2: Washing & Drying (Liner Pre-treatment)

Description: Once knitted, the glove liners undergo a thorough washing process to remove any impurities, oils, or loose fibers from the knitting process. This cleaning step is crucial to ensure optimal adhesion of the subsequent coating. After washing, the liners are dried completely in controlled environments to prevent any moisture interference during coating.

LINER WASHING → THOROUGH DRYING

-

Stage 3: Dipping & Coating Application

Description: This is the core stage where the protective smooth coating is applied. The dried glove liners are mounted onto ceramic or metal formers (hand-shaped molds). These formers, with the liners, are then dipped into large vats containing liquid polymer compounds (Nitrile, PU, or Latex emulsions). The dipping depth can be full-hand or palm-only, depending on the required protection. For a smooth coating, the dip is typically single-layer and evenly spread. Precise control over dipping speed and dwell time is critical for uniform coating thickness and consistency.

Key Manufacturing Process: Dipping (Wet-on-Wet or Multi-dip for specific properties). The smooth coating finish minimizes surface friction and allows for easy cleaning, while maintaining excellent waterproof and wear-resistant properties.

LINER MOUNTING ON FORMERS → POLYMER DIPPING (Controlled Immersion)

-

Stage 4: Curing/Vulcanization

Description: After dipping, the coated gloves undergo a curing or vulcanization process. This typically involves passing the gloves through a heated oven. The heat causes the liquid polymer to solidify and cross-link, transforming it into a durable, elastic, and strong protective layer. The specific temperature and duration of curing depend on the polymer type and desired properties. This process permanently bonds the coating to the liner, ensuring its integrity and performance, especially for the waterproof and wear-resistant features.

HEAT CURING / VULCANIZATION

-

Stage 5: Stripping & Initial Inspection

Description: Once cured, the gloves are carefully stripped off the formers, usually with the aid of air jets or automated mechanisms. A preliminary visual inspection is conducted at this stage to check for obvious defects like tears, inconsistent coating, or pinholes that would compromise the glove's waterproof integrity. This initial check ensures basic quality control.

GLOVE STRIPPING → VISUAL CHECK

-

Stage 6: Final Quality Control & Testing

Description: This is a critical stage for ensuring that the Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant meet all specified performance standards. Gloves are subjected to rigorous testing according to international standards like EN 388, EN ISO 374, and ANSI/ISEA 105. Tests include:

- Mechanical Performance Tests: Abrasion, cut, tear, and puncture resistance tests using specialized equipment.

- Waterproof Test: Often involving a water column or immersion test to verify the integrity of the coating against liquid penetration.

- Chemical Permeation Test (if applicable): For gloves claiming chemical resistance, samples are exposed to specific chemicals to measure breakthrough time.

- Visual Inspection: Detailed checks for aesthetic flaws, sizing consistency, and overall finish.

Detection Standards: ISO 9001 quality management system certification ensures consistent production quality. Each batch is subject to statistical process control (SPC) and AQL (Acceptable Quality Limit) sampling to maintain high standards.

RIGOROUS TESTING (EN/ANSI) → FINAL VISUAL INSPECTION

-

Stage 7: Packaging & Warehousing

Description: After passing all quality checks, the gloves are paired, folded, and packaged according to customer specifications (e.g., polybags, dozen packs, master cartons). Proper labeling with size, standard compliance, and batch information is applied. The finished products are then moved to warehousing for distribution.

Usage Lifespan: With proper care and storage, the expected lifespan of these gloves is typically 1-3 years from the manufacturing date, though actual usage lifespan in industrial settings varies based on application intensity and hazard exposure.

PAIRING & PACKAGING → WAREHOUSING & DISTRIBUTION

Technical Advantages of Wholesale High Quality Smooth Coated Industrial Gloves

The design and construction of Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant confer several distinct technical advantages that set them apart in the industrial PPE market:

- Superior Waterproofing: The smooth coating, typically a full dip, creates an impermeable barrier against liquids. This is crucial in wet environments, preventing water, oils, and other fluids from penetrating the glove and reaching the hand, thereby maintaining hand dryness, comfort, and preventing skin irritations or infections. This feature is particularly beneficial in industries like wastewater treatment, chemical handling (non-corrosive, splash protection), and food processing.

- Exceptional Wear Resistance: The robust polymer coating (Nitrile or high-grade PU) is engineered to withstand significant abrasion and friction. This translates to a longer service life for the gloves, even in demanding tasks involving rough surfaces or repetitive movements. This durability reduces the frequency of glove replacement, leading to cost savings for businesses.

- Enhanced Grip in Various Conditions: While the coating is "smooth," advanced formulations often incorporate micro-textures or specific polymer blends that provide excellent grip in both dry and wet/oily conditions. This is a critical safety feature, as secure grip prevents slippage of tools or materials, reducing the risk of accidents and improving work efficiency.

- Optimized Dexterity and Tactile Sensitivity: Despite their protective qualities, these gloves are designed with thin yet strong coatings and seamless liners (e.g., 13 or 15 gauge) that allow for a high degree of finger movement and tactile feedback. This balance is vital for tasks requiring precision and fine motor skills, ensuring workers can perform complex operations without removing their gloves, thus maintaining continuous protection.

- Comfort and Breathability: The advanced liner materials (Nylon/Polyester) provide a comfortable fit, reducing hand fatigue during prolonged use. While fully coated gloves inherently have less breathability than palm-coated ones, the smooth coating often allows for easier cleaning and reduces material absorption, contributing to hygiene.

- Versatile Chemical Splash Protection: While not designed for immersion in hazardous chemicals, the smooth, impermeable coating offers reliable splash protection against a range of common industrial liquids, oils, and greases. This extends their utility across various applications where incidental contact with non-corrosive liquids is common.

Choosing the Right Manufacturer: Beyond the Product

When sourcing Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant, selecting the right manufacturer is as crucial as the product itself. A reputable manufacturer offers not just a product, but a partnership built on reliability, quality assurance, and customer support. Here are key aspects to consider for manufacturer comparison:

- Certifications & Quality Management: Look for manufacturers with internationally recognized certifications such as ISO 9001:2015 for Quality Management Systems. This indicates a commitment to consistent quality and continuous improvement in their manufacturing processes. Adherence to specific product standards like EN 388, EN ISO 374, and ANSI/ISEA 105 must be verifiable through credible testing reports from accredited labs.

- Research & Development (R&D) Capabilities: A forward-thinking manufacturer invests in R&D to innovate and improve glove performance. This translates to products that integrate the latest material science, coating technologies, and ergonomic designs, providing superior protection and comfort. Inquire about their track record in developing new or improved glove types.

- Customization and OEM/ODM Services: For large-scale procurement or specific industrial needs, the ability to offer OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) services is a significant advantage. This allows for tailored solutions regarding material blends, coating thicknesses, sizing, branding, and packaging to perfectly match your operational requirements.

- Production Capacity & Delivery Reliability: Assess their production capacity to ensure they can meet your volume demands, especially for wholesale orders. A reliable manufacturer will have robust supply chain management and a proven track record of on-time delivery, minimizing operational disruptions for your business.

- Customer Service & Technical Support: Evaluate their responsiveness, willingness to provide technical data sheets, samples, and after-sales support. A manufacturer that offers comprehensive technical guidance helps you select the right gloves and resolve any in-use issues efficiently.

- Environmental and Social Responsibility: Increasingly, businesses are prioritizing suppliers with ethical manufacturing practices and environmental consciousness. Inquire about their sustainability initiatives, waste management, and fair labor practices (e.g., adherence to BSCI or Sedex principles).

Tailored Protection: Customization Solutions

Recognizing that one size does not fit all in industrial safety, we offer comprehensive customization solutions for Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant. Our goal is to provide protective solutions that precisely match the unique demands of your industry and specific applications. Our customization capabilities include:

- Material Configuration:

- Liner Material: Choice of different gauges (e.g., 10G, 13G, 15G) and blends (Nylon, Polyester, HPPE, Spandex) to adjust comfort, dexterity, and cut resistance levels. For instance, a higher HPPE content for increased cut protection.

- Coating Material: Selection among Nitrile, PU, or Latex to optimize for chemical resistance, oil grip, or dry tactile sensitivity. We can also adjust the formulation for specific properties like enhanced flexibility or additional abrasion resistance.

- Coating Style & Thickness:

- Full Dip vs. Palm Dip: While the primary product is fully coated for maximum waterproofing, we can customize to palm-only dips if breathability on the back of the hand is prioritized for certain dry, less hazardous applications.

- Coating Thickness: Fine-tuning the coating thickness to balance protection and dexterity. A slightly thicker coating for heavy-duty abrasion, or thinner for precision tasks.

- Sizing and Fit: Beyond standard XS-XXL, we can provide precise sizing adjustments to ensure an optimal ergonomic fit, which is critical for comfort and reducing hand fatigue.

- Branding and Packaging:

- Private Labeling/OEM: Imprint your company logo or branding on the gloves themselves or on the packaging.

- Custom Packaging: Design and supply custom polybags, header cards, inner boxes, and master cartons with your specific branding, product information, and regulatory labels.

- Specialized Treatments:

- Anti-Bacterial/Anti-Odor Treatment: Incorporating agents to inhibit bacterial growth and odor, enhancing hygiene and comfort for prolonged use.

- Touchscreen Compatibility: Integrating conductive materials into fingertips for seamless interaction with touch-enabled devices without removing gloves.

- Hi-Vis Colors: Offering bright, high-visibility colors for enhanced safety in low-light environments.

Our expert team works closely with clients to understand their unique requirements, offering tailored advice and prototypes to ensure the final product meets their exact specifications and performance expectations. This collaborative approach ensures that your investment in Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant delivers maximum value and safety.

Real-World Application Scenarios and Case Studies

The versatility and robust protective qualities of Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant make them indispensable across a wide array of industrial sectors. Their waterproof, wear-resistant, and high-dexterity features solve common challenges faced by workers in demanding environments.

Typical Application Industries:

- Oil and Gas (Upstream & Downstream): Protection against oil, grease, hydrocarbons, and mechanical hazards during drilling, refining, and maintenance operations. The smooth coating prevents absorption and provides excellent wet grip.

- Automotive Manufacturing & Assembly: Handling components, general assembly, engine maintenance, where protection from oils, coolants, and sharp edges is needed without sacrificing dexterity.

- Construction & Infrastructure: General handling of materials, operating machinery, plumbing, and electrical work where exposure to dirt, moisture, and abrasive surfaces is common.

- Logistics & Warehousing: Handling packages, operating forklifts, sorting, and general labor where abrasion resistance and good grip are essential for efficiency and safety.

- General Maintenance & Repair: For technicians performing routine checks, repairs, and cleaning across various industries, providing all-around hand protection.

- Water & Wastewater Treatment: Protection against water, sludge, and certain non-corrosive chemicals encountered during plant operations and maintenance.

- Agriculture & Fisheries: Protection against moisture, dirt, and minor abrasions while handling produce, equipment, or working in wet conditions.

- Recycling & Waste Management: Handling various types of waste materials, requiring robust abrasion, puncture, and waterproof protection.

Simulated Application Cases:

Case Study 1: Automotive Engine Assembly Line

Challenge: Workers on an engine assembly line frequently handle components coated with lubricants and coolants, requiring gloves that offer excellent grip in oily conditions, high dexterity for intricate tasks, and resistance to oils and abrasions. Traditional gloves often became saturated with oil, compromised grip, or quickly wore out.

Solution: Implementation of Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant with a Nitrile smooth coating. The nitrile provided a superior barrier against oils and chemicals while offering exceptional wet grip. The 15-gauge liner ensured high dexterity for handling small fasteners and tools.

Results: A 30% reduction in hand injuries related to slips and abrasions. Workers reported significantly improved grip and comfort, leading to increased productivity and reduced glove consumption by 25% due to enhanced durability. The gloves were easy to clean, contributing to better hygiene.

Case Study 2: Municipal Wastewater Treatment Plant Maintenance

Challenge: Maintenance teams at a wastewater treatment plant were constantly exposed to water, sludge, and various non-hazardous liquids. Their existing gloves became waterlogged, leading to discomfort, skin issues, and reduced grip, especially when handling wet pipes and valves. Longevity was also a concern due to constant moisture and abrasive surfaces.

Solution: Adoption of Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant with a full, waterproof smooth coating. The gloves effectively kept hands dry, significantly improving comfort and preventing dermatological issues. The wear-resistant coating stood up to the rigors of handling rough, wet equipment.

Results: A dramatic improvement in worker comfort and satisfaction. The incidence of skin irritation and hand-related discomfort dropped by over 40%. Glove replacement rates decreased by 20%, demonstrating their superior durability in a consistently wet and abrasive environment. The enhanced grip facilitated safer handling of slippery components.

Building Trust: Warranty, Delivery, and Customer Support

At the core of our operations is a commitment to trustworthiness and customer satisfaction. We understand that purchasing industrial PPE is an investment in safety and efficiency, and we back our Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant with robust support mechanisms.

Quality Assurance & Warranty:

All our Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant undergo stringent quality control processes, adhering to ISO 9001 standards, and are certified to relevant international safety standards like EN 388. We offer a standard manufacturer's warranty against defects in materials and workmanship. This warranty typically covers issues arising from manufacturing flaws that impact the glove's intended performance. Our commitment ensures that you receive products that meet or exceed industry expectations for quality and safety.

Delivery Cycle & Logistics:

We pride ourselves on efficient and reliable delivery schedules. For wholesale orders of Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant, our typical lead time for standard products is 3-5 weeks from order confirmation, depending on volume and customization requirements. For urgent requests or large-scale projects, we work closely with clients to develop expedited production and shipping plans. We partner with reputable global logistics providers to ensure timely and secure delivery to your specified location, complete with tracking capabilities and customs assistance for international shipments.

Dedicated Customer Support:

Our commitment extends beyond the sale. We provide comprehensive customer support, including:

- Expert Consultation: Our team of PPE specialists is available to provide detailed product information, technical specifications, and guidance on selecting the most appropriate gloves for your specific applications and hazards.

- Technical Support: Assistance with product performance data, understanding certifications, and addressing any technical queries you may have.

- After-Sales Service: Prompt and efficient handling of any concerns, quality feedback, or warranty claims. Our goal is to ensure your complete satisfaction with our products and services.

- Training Resources: Where appropriate, we can provide resources or guidance on proper glove usage, maintenance, and storage to maximize their lifespan and protective efficacy.

Frequently Asked Questions (FAQ)

Here are answers to some common professional questions regarding Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant:

Answer: "Smooth Coated" refers to the finish of the polymer coating (e.g., Nitrile, PU, Latex) applied to the glove liner. Unlike foamed, sandy, or crinkle finishes which have textured surfaces for enhanced grip, a smooth coating presents a uniform, sleek surface. This finish is particularly beneficial for applications requiring good tactile sensitivity, ease of cleaning, and resistance to liquid penetration, as it prevents absorption of oils or fluids into the coating itself. It also provides excellent grip in dry and many wet/oily conditions due to specific polymer formulations.

Answer: The "Waterproof" property is primarily achieved through the full, impermeable polymer coating (e.g., Nitrile or Latex) that creates a barrier against liquids. The coating is applied evenly and cured to form a robust, non-porous layer. "Wear Resistant" refers to the glove's ability to withstand abrasion and friction. This is due to the inherent durability of the selected coating polymers (like high-grade Nitrile) combined with precise coating thickness and a strong bond to the liner, as validated by high abrasion scores in EN 388 testing (e.g., Level 4).

Answer: The service life of Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant is significantly longer than uncoated fabric gloves due to the protective polymer coating. While actual lifespan depends heavily on the specific application, frequency of use, and handling of abrasive materials, these gloves are designed for extended use, often lasting several times longer than their uncoated counterparts. Their "wear-resistant" designation directly relates to this extended durability.

Answer: While "waterproof" means resistant to water and many non-hazardous liquids, it does not automatically imply resistance to all hazardous chemicals. These gloves offer excellent splash protection against oils, greases, and many non-corrosive industrial liquids. For handling specific hazardous chemicals, it is crucial to consult the glove's chemical permeation data (EN ISO 374 ratings) to ensure compatibility and sufficient barrier protection against the particular chemical agents involved. They are generally suitable for incidental chemical splash, not immersion in strong chemicals.

Answer: "Gauge" refers to the number of stitches per inch on a knitting machine. A higher gauge number (e.g., 15-gauge or 18-gauge) indicates a finer, denser knit, resulting in a thinner glove liner. This translates to increased dexterity, tactile sensitivity, and often a more comfortable, snug fit, making it ideal for precision tasks. Lower gauges (e.g., 7-gauge or 10-gauge) produce thicker, bulkier liners that offer more cushioning and warmth, often used for heavy-duty applications.

Answer: Smooth coatings excel in providing excellent grip in dry conditions and often perform well in light oil and wet environments due to the specific polymer's inherent grip properties. Textured coatings (like sandy or foam finishes) are designed to provide superior grip in heavily oily or wet conditions by channeling liquids away or creating micro-suction effects. The choice depends on the specific workplace environment: smooth for general-purpose wet/dry and oil splash, textured for heavy oil/water immersion where maximum grip is paramount.

Answer: Yes, generally, Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant with polymer coatings can be cleaned for reuse, enhancing their lifespan and cost-effectiveness. Best practices typically involve hand washing with mild soap and water, rinsing thoroughly, and air-drying away from direct heat or sunlight. Avoid harsh chemicals, bleach, or machine washing/drying unless specifically stated by the manufacturer, as these can degrade the coating and compromise the glove's protective properties. Regular cleaning helps maintain hygiene and extend the glove's effective life.

Conclusion: Redefining Hand Protection in Industry

The Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant represent a significant advancement in industrial hand protection. By combining state-of-the-art materials with meticulous manufacturing processes, these gloves deliver an unparalleled blend of waterproofing, exceptional wear resistance, superior grip, and ergonomic comfort. They address the critical needs of a diverse range of industries, from the demanding environments of oil and gas to the precision-focused assembly lines of automotive manufacturing.

Investing in these high-quality, smooth-coated gloves translates directly into enhanced worker safety, reduced injury rates, and increased operational efficiency. Their durability minimizes replacement costs, while their comfort promotes consistent compliance among workers. As industries continue to evolve, the demand for sophisticated, multi-functional PPE like these gloves will only grow. By choosing a reputable manufacturer committed to quality, innovation, and customer support, businesses can ensure they are providing their workforce with the best possible protection, fostering a safer, more productive, and more sustainable work environment. Embrace the future of hand safety with gloves designed for the challenges of today and tomorrow.

References and Further Reading:

- International Labour Organization (ILO) - Safety and Health at Work: https://www.ilo.org/global/topics/safety-and-health-at-work/lang--en/index.htm

- European Committee for Standardization (CEN) - EN 388 Standard for Protective Gloves Against Mechanical Risks: https://standards.cen.eu/dyn/www/f?p=204:110:0::::FSP_PROJECT,FSP_LANG_ID:68171,27&cs=124036136D20CC5D4D540A61908C8F7E4

- Occupational Safety and Health Administration (OSHA) - Hand Protection Guidance: https://www.osha.gov/hand-protection

- ResearchGate - "Advances in Protective Textiles": https://www.researchgate.net/publication/282664929_Advances_in_Protective_Textiles

- Industrial Safety & Hygiene News (ISHN) - Latest Trends in Hand Protection: https://www.ishn.com/topics/protective-gloves