Wholesale Waterproof Industrial Gloves: Smooth Coated, Wear Resistant

The Evolution of Industrial Protection: Understanding **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant**

In today's demanding industrial landscape, worker safety and efficiency are paramount. Protective handwear, especially industrial gloves, plays a critical role in preventing injuries and enhancing productivity across countless sectors. Among the most sought-after solutions are **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant**. These specialized gloves are engineered to offer a superior blend of protection, comfort, and durability, addressing the complex challenges faced by professionals in wet, oily, or abrasive environments. This comprehensive guide delves into the specifics of these advanced gloves, exploring their market trends, technical prowess, application versatility, and the manufacturing excellence that sets them apart.

Industry Trends and Market Dynamics in Industrial Hand Protection

The global market for industrial protective gloves is experiencing robust growth, driven by increasing awareness of workplace safety, stringent regulatory compliance, and the continuous innovation in material science and manufacturing technologies. According to a report by Grand View Research, the global industrial protective gloves market size was valued at USD 6.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030. This growth is significantly fueled by the rising demand for specialized gloves like **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant**, which offer enhanced performance attributes over traditional counterparts.

Key trends shaping this market include:

- Technological Advancements: Continuous innovation in polymer coatings (e.g., nitrile, polyurethane, PVC), fabric knitting technologies, and ergonomic designs.

- Sustainability Focus: Growing demand for eco-friendly manufacturing processes and recyclable materials, driven by environmental regulations and corporate social responsibility initiatives.

- Increased Customization: Manufacturers are offering more tailored solutions to meet specific industry needs, including varying levels of cut, abrasion, and chemical resistance.

- Automation and Robotics: The rise of automation in manufacturing processes necessitates gloves that can interact effectively with machinery while providing superior protection.

- Demand for Multi-functional Gloves: Preference for gloves that offer multiple protective features (e.g., waterproof, wear-resistant, anti-oil, anti-impact) in a single product, optimizing inventory and user convenience.

The emphasis on waterproofing and wear resistance highlights a critical need in industries where exposure to liquids, chemicals, and abrasive surfaces is common. Workers require gloves that not only keep their hands dry but also maintain structural integrity and grip performance over extended periods, directly contributing to safety and efficiency.

Unpacking the Technical Parameters of Advanced Industrial Gloves

The superior performance of **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant** is rooted in their meticulously engineered technical specifications. Understanding these parameters is crucial for procurement managers and safety officers to select the right product for their specific operational demands. Here’s a breakdown of typical specifications:

Product Specifications Table: **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant**

| Parameter | Description | Typical Value/Standard |

|---|---|---|

| Product Name | Premium industrial gloves designed for robust protection. | Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant |

| Base Material (Liner) | High-quality knit material providing comfort and breathability. | Polyester, Nylon, Cotton Blend (e.g., 13-gauge seamless knit) |

| Coating Material | Polymer coating providing waterproofing, grip, and abrasion resistance. | Nitrile, Polyurethane (PU), PVC, Latex (Smooth Finish) |

| Coating Type | Full or palm/finger dipped coating. | Smooth Coated (Full or 3/4 Dip) |

| Waterproof Rating | Ability to repel liquids effectively. | Excellent, Impervious to Water/Oil |

| Abrasion Resistance | Resistance to surface wear caused by rubbing or scraping. | EN 388:2016 Level 4 (out of 4) |

| Cut Resistance | Protection against cuts by sharp objects. | EN 388:2016 Level X (A-F, varies by specific model) |

| Tear Resistance | Resistance to tearing when subjected to force. | EN 388:2016 Level 4 (out of 4) |

| Puncture Resistance | Resistance to penetration by pointed objects. | EN 388:2016 Level 2-3 (out of 4) |

| Dexterity | Ability to perform fine motor tasks while wearing gloves. | High, Good Tactile Sensitivity |

| Grip Performance | Effectiveness of grip in wet, dry, or oily conditions. | Excellent (Smooth Coated, but designed for specific grip patterns) |

| Thickness | Overall glove thickness. | Varies (typically 0.8mm - 1.2mm) |

| Sizes Available | Range of sizes to fit different hand dimensions. | S, M, L, XL, XXL (Size 7-11) |

| Certifications | Adherence to international safety standards. | CE (EN 388:2016, EN ISO 21420:2020), ISO 9001 |

| Service Life | Expected durability under normal usage conditions. | Significantly extended due to high wear resistance |

These parameters are often quantified using international standards such as EN 388:2016, which assesses mechanical risks including abrasion, cut, tear, and puncture resistance. A high rating (e.g., Level 4 for abrasion) signifies superior protection and durability, making these gloves ideal for strenuous industrial applications. The "smooth coated" aspect, while implying a lack of textured grip, often refers to a particular type of polymer finish that excels in specific handling tasks where sensitivity or non-marking properties are critical, while the underlying material and specific polymer blend ensure effective grip even in wet conditions.

Application Scenarios: Where **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant** Excel

The versatility of **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant** makes them indispensable across a broad spectrum of industries. Their unique combination of waterproof properties, exceptional wear resistance, and comfortable design ensures optimal hand protection in challenging environments.

Typical application scenarios include:

- Automotive Industry: Handling oily components, assembling parts, maintenance, and working in wet conditions. The smooth coating often prevents marring of finished surfaces while providing necessary protection and grip.

- Construction & Building: Handling wet or abrasive materials, bricklaying, concrete work, and general site maintenance. Their robust construction protects against splinters, sharp edges, and prolonged moisture exposure.

- Manufacturing & Assembly: Precision tasks involving oils, coolants, or lubricants, general assembly lines, and material handling. High dexterity combined with protection is crucial here.

- Logistics & Warehousing: Handling goods in various conditions, including outdoor environments or cold storage where moisture can be an issue. The wear resistance ensures longevity despite constant friction.

- Oil & Gas / Petrochemical: Working with petroleum products, solvents, and water. These gloves offer chemical splash resistance and excellent grip in oily environments, crucial for safety in hazardous settings.

- Agriculture & Fishing: Protecting hands from water, dirt, and light chemicals, while ensuring a secure grip on tools and produce.

- Utilities (Water/Wastewater Treatment, Electrical): Performing maintenance or operational tasks in wet or dirty environments. The waterproof nature is vital for hygiene and comfort.

- Mining: Handling abrasive rocks and tools in damp or wet conditions.

- Metal Fabrication: Protecting against oils, greases, and light abrasions during cutting, grinding, and forming processes.

In each of these scenarios, the key advantages – waterproofing, wear resistance, and smooth coating for specific handling needs – contribute directly to worker safety, comfort, and sustained productivity. For instance, in a busy automotive assembly line, workers handling oily engine parts benefit immensely from gloves that prevent oil penetration, maintain excellent grip, and withstand repetitive motion without quickly degrading. This directly reduces the risk of slips, contamination, and skin irritation, enhancing overall operational efficiency.

Technical Advantages: Beyond Basic Protection

The technical superiority of **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant** lies in their advanced design and material science. These gloves offer several distinct advantages that elevate them beyond standard industrial hand protection:

- Exceptional Waterproofing: The specialized smooth coating (often nitrile or PVC based) forms an impermeable barrier against water, oils, and certain chemicals. Unlike conventional gloves that may absorb liquids, these gloves ensure hands remain dry, preventing skin irritation, dermatitis, and maintaining a firm grip even in saturated conditions. This is critical in applications like plumbing, chemical handling, or outdoor work.

- Superior Wear and Abrasion Resistance: The robust coating material, combined with durable liner fabrics, provides outstanding resistance to abrasion, cuts, and tears. This significantly extends the gloves' service life, reducing replacement costs and ensuring consistent protection over time. For example, a glove rated EN 388 Level 4 for abrasion can withstand thousands of cycles of rubbing before showing signs of wear, far exceeding less robust alternatives.

- Enhanced Durability and Longevity: By resisting wear and tear, these gloves maintain their protective integrity for longer periods. This translates to fewer glove changes, less downtime, and a more sustainable safety program. The longevity is a direct result of the high-quality base materials and the resilient polymer coating processes.

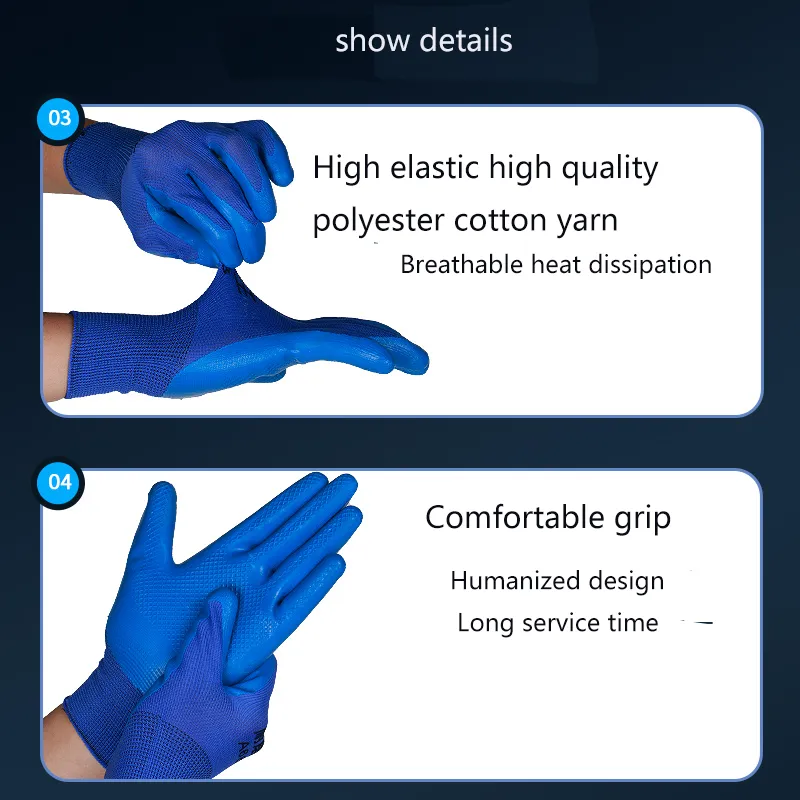

- Optimized Dexterity and Tactile Sensitivity: Despite their robust protection, modern manufacturing techniques allow these smooth-coated gloves to retain a high degree of flexibility and tactile sensitivity. This enables workers to perform intricate tasks, handle small components, and operate machinery with precision, without compromising safety. The smooth finish is particularly beneficial where a "non-stick" surface or reduced friction is desired, or when handling sensitive components to prevent marking.

- Comfort and Ergonomics: The seamless knit liners (e.g., 13-gauge) are designed for comfort, reducing hand fatigue during prolonged use. They are breathable, managing sweat and heat, and the ergonomic fit minimizes bulkiness, allowing for natural hand movement.

- Cost-Effectiveness: While the initial investment might be slightly higher than basic gloves, their extended service life and superior protection lead to significant long-term savings by reducing injury rates, healthcare costs, and the frequency of glove procurement.

Manufacturing Excellence: The Process Behind **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant**

The production of **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant** is a sophisticated multi-stage process that combines advanced knitting technology with precise chemical dipping and curing techniques. This intricate process ensures the gloves meet rigorous quality and performance standards. Here’s a detailed breakdown:

Manufacturing Process Flow:

[Textual Representation of Process Flow]

- Knitting the Liner:

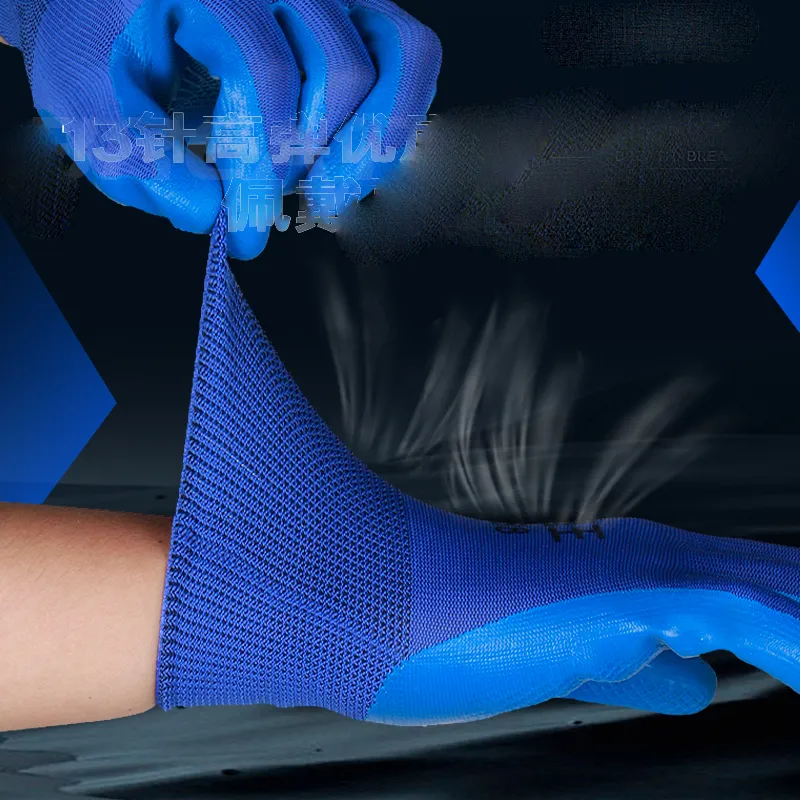

- Process: High-speed automated knitting machines use fine-gauge yarns (e.g., 13-gauge, 15-gauge, or 18-gauge polyester, nylon, or cotton blends) to produce seamless glove liners. This creates the foundational structure and determines the initial comfort and dexterity.

- Key Node: Precise tension control and yarn selection.

- Material Highlight: Polyester and nylon offer durability and moisture-wicking properties, while cotton provides breathability and softness.

- Forming and Washing:

- Process: The knitted liners are placed onto ceramic or metal hand molds (formers). They then undergo a thorough washing cycle to remove any impurities, oils, or loose fibers, ensuring optimal adhesion of the subsequent coating.

- Key Node: Cleanliness and mold preparation.

- Coating Preparation (Dipping Solution):

- Process: The specific polymer coating material (Nitrile, PU, PVC, or Latex) is prepared as a liquid emulsion or compound. This involves precise mixing of polymers, curing agents, pigments, and other additives to achieve desired properties like flexibility, grip, and chemical resistance.

- Key Node: Chemical formulation and viscosity control.

- Dipping Process:

- Process: The glove formers, with their liners, are precisely dipped into the coating solution. The dipping depth and speed are meticulously controlled to achieve the desired coating thickness and coverage (e.g., full dip, palm dip, 3/4 dip). For smooth coated gloves, the dipping process focuses on creating an even, uniform layer without textured patterns.

- Key Node: Controlled dipping parameters, ensuring even coating.

- Manufacturing Craft: This step is critical for waterproofing and wear resistance. The specific polymer chosen dictates the glove's primary protective characteristics:

- Nitrile: Excellent resistance to oils, greases, and punctures. Highly durable and offers good grip.

- Polyurethane (PU): Known for high dexterity, elasticity, and good abrasion resistance, often used for precision work.

- PVC (Polyvinyl Chloride): Good resistance to chemicals, abrasives, and oils, often used for heavy-duty applications.

- Latex: High elasticity, tear resistance, and excellent grip, but can cause allergic reactions.

- Drying and Curing (Vulcanization):

- Process: After dipping, the coated gloves are moved through drying ovens where heat initiates the curing process (often vulcanization for rubber-based coatings). This cross-links the polymer chains, transforming the liquid coating into a solid, durable, and protective layer. This step is crucial for achieving the final physical properties like wear resistance and impermeability.

- Key Node: Temperature and time control for optimal polymer cross-linking.

- Finishing and Stripping:

- Process: Once cured, the gloves are cooled. Additional finishing processes, such as adding cuffs or anti-bacterial treatments, may occur. The gloves are then mechanically stripped from the formers.

- Key Node: Efficient stripping without damaging the glove.

- Quality Inspection and Packaging:

- Process: Each glove undergoes stringent quality checks, including visual inspection for defects, air inflation tests for waterproofing integrity, and random sampling for performance testing (e.g., EN 388, EN ISO 21420). Only gloves meeting the strict quality control standards are packaged for distribution.

- Key Node: Adherence to international standards (e.g., ISO 9001 for quality management, EN 388, EN ISO 21420:2020 for protective gloves).

Throughout this process, continuous monitoring and precise calibration are essential to produce high-quality, consistent **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant**. The focus on specific material choices and controlled dipping techniques is what imbues these gloves with their characteristic waterproof nature and exceptional resistance to wear.

Manufacturer Comparison: Choosing the Right Supplier for **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant**

When sourcing **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant**, selecting the right manufacturer or supplier is as crucial as the product itself. A reliable partner ensures consistent quality, competitive pricing, and dependable supply. Here's a comparative overview of factors to consider:

Key Manufacturer/Supplier Comparison Factors

| Factor | Description | Benefits for Buyer |

|---|---|---|

| Experience & Reputation | Years in the industry, positive client testimonials, proven track record. | Ensures reliability, product consistency, and industry knowledge. Our company has extensive experience in the industrial safety sector, serving clients globally for over a decade. |

| Certifications & Compliance | Adherence to international standards (ISO 9001, CE, EN 388, etc.), ethical manufacturing. | Guarantees product safety, performance, and legal compliance. We adhere strictly to EN 388:2016 and EN ISO 21420:2020. |

| Product Range & Specialization | Focus on specific glove types, breadth of catalog. | Access to specialized solutions tailored to specific needs, indicating expertise. We specialize in high-performance coated industrial gloves. |

| R&D and Innovation | Investment in new materials, designs, and manufacturing processes. | Access to cutting-edge products, continuous improvement, and problem-solving capabilities. We continuously innovate our coating formulations and liner technologies. |

| Customization Capabilities | Ability to tailor products (e.g., size, color, coating, branding). | Ensures perfect fit for unique operational requirements and brand integration. We offer comprehensive OEM/ODM services. |

| Supply Chain & Logistics | Efficiency of production, inventory management, shipping capabilities. | Reliable delivery, reduced lead times, minimized stockouts. Optimized global logistics network for timely delivery. |

| Customer Support & After-Sales Service | Responsiveness, technical assistance, warranty, returns policy. | Builds long-term partnerships, ensures quick resolution of issues, and trust. Dedicated multilingual support team and clear warranty policies. |

| Pricing & MOQ | Competitive pricing, flexible Minimum Order Quantities. | Better cost management and flexibility for businesses of all sizes. Competitive wholesale pricing structure with negotiable MOQs for large orders. |

Our commitment to quality, innovation, and customer satisfaction positions us as a leading choice for **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant**. We understand the critical nature of industrial safety and strive to provide products that not only meet but exceed industry benchmarks.

Custom Solutions and OEM/ODM Opportunities

Recognizing that no two industrial environments are exactly alike, we offer extensive customization options and robust OEM/ODM (Original Equipment Manufacturer/Original Design Manufacturer) services for **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant**. This allows businesses to acquire gloves that are perfectly aligned with their specific operational demands, brand identity, and safety protocols.

Our customization capabilities include:

- Material Selection: Tailoring the liner material (e.g., cut-resistant fibers, thermal insulation) and coating compound (e.g., specific chemical resistance, enhanced abrasion properties).

- Coating Type and Finish: Adjusting the thickness of the smooth coating, or even incorporating specific additives for anti-static properties, or different levels of grip (though the core product remains smooth-coated, nuances are possible).

- Sizing and Fit: Developing custom molds or scaling existing designs to accommodate unique hand dimensions or ergonomic requirements for specialized tasks.

- Color and Branding: Customizing glove colors to match company uniforms or safety coding systems, and integrating client logos or specific labeling.

- Performance Enhancements: Incorporating additional features such as touchscreen compatibility, extended cuffs, or specific thermal protection.

- Packaging: Custom packaging solutions, including private labeling, bulk packaging, or retail-ready designs.

Our OEM/ODM process is collaborative, beginning with a detailed understanding of the client's needs, followed by design, prototyping, rigorous testing, and finally, mass production. This ensures that the final product, whether it's a bespoke version of our **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant** or an entirely new design, delivers optimal performance and satisfaction.

Real-World Application Cases and Success Stories

The practical benefits of **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant** are best illustrated through their successful implementation in various industrial settings. These case studies highlight their tangible impact on worker safety, efficiency, and cost savings.

Case Study 1: Automotive Assembly Line - Reduced Hand Injuries and Enhanced Productivity

- Challenge: A major automotive manufacturer faced persistent issues with hand injuries (cuts, abrasions, skin irritation from oil exposure) and frequent glove replacements in their engine assembly division. Workers handled numerous oily components, requiring both protection and high dexterity.

- Solution: They transitioned to our **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant** with a high-dexterity nitrile smooth coating.

- Outcome:

- Injury Reduction: Within six months, reported hand injuries related to cuts, abrasions, and chemical exposure dropped by 35%.

- Glove Longevity: The wear resistance extended glove lifespan by over 50%, significantly reducing procurement costs.

- Productivity Boost: Workers reported improved grip on oily parts and enhanced tactile sensitivity, leading to a 10% increase in assembly line efficiency due to less fumbling and fewer breaks for glove changes.

Case Study 2: Municipal Water Treatment Plant - Improved Safety in Wet Environments

- Challenge: Workers at a water treatment facility frequently dealt with wet, slippery surfaces and exposure to various treatment chemicals. Their previous gloves became waterlogged, compromised grip, and offered insufficient protection against mild chemical splashes.

- Solution: The plant adopted our **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant**, specifically selecting a PVC-coated variant for its superior waterproofing and chemical splash resistance.

- Outcome:

- Enhanced Safety: The complete waterproof barrier prevented skin contact with treated water and mild chemicals, reducing instances of skin irritation and infection to nearly zero.

- Reliable Grip: The smooth coating, while seemingly counter-intuitive, proved effective in providing excellent grip on wet pipes and machinery, preventing slips and drops.

- Worker Comfort: Hands remained dry and comfortable, even during long shifts in damp conditions, improving morale and reducing fatigue.

These examples underscore how choosing the right specialized hand protection, like **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant**, translates directly into a safer, more efficient, and more cost-effective operation. The investment in high-quality PPE yields significant returns in reduced accidents, improved worker well-being, and enhanced operational continuity.

Ensuring Trustworthiness: Our Commitment to Quality and Support

Building long-term partnerships is at the core of our business philosophy. We understand that trustworthiness is paramount in the safety industry. Our commitment to quality, transparency, and customer support for **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant** is reflected in several key areas:

- Rigorous Quality Control: Every batch of gloves undergoes multi-stage quality inspections, from raw material sourcing to finished product testing. We adhere to international quality management systems such as ISO 9001, ensuring consistent product excellence. Our products are tested against relevant EN standards, including EN 388:2016 and EN ISO 21420:2020 (General requirements for protective gloves).

- Transparent Certifications: All our **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant** come with verifiable CE markings and comprehensive testing reports, providing full transparency on their protective capabilities and compliance with European safety directives.

- Comprehensive Warranty: We stand by the durability and performance of our gloves. Our products are backed by a clear warranty policy against manufacturing defects, ensuring peace of mind for our clients.

- Reliable Delivery Cycle: We maintain efficient production schedules and robust logistics partnerships to ensure timely delivery of orders, minimizing downtime for our clients. Standard delivery typically ranges from 15-30 days, depending on order volume and customization requirements. Expedited shipping options are available upon request.

- Dedicated Customer Support: Our team of experts is available to provide technical assistance, product recommendations, and after-sales support. From initial inquiry to post-purchase queries, we are committed to responsive and helpful service.

- Client Feedback Integration: We actively solicit and integrate customer feedback into our product development and service improvement processes, ensuring our offerings continually meet evolving market needs.

By focusing on these pillars of trustworthiness, we aim to be more than just a supplier; we aspire to be a reliable partner in your safety solutions.

Frequently Asked Questions (FAQ) about **Wholesale High Quality Smooth Coated Industrial Gloves Waterproof And Wear Resistant**

References and Further Reading:

- Global Industrial Protective Gloves Market Size, Share & Trends Analysis Report: https://www.grandviewresearch.com/industry-analysis/industrial-protective-gloves-market

- European Standard EN 388:2016 - Protective gloves against mechanical risks: https://www.iso.org/standard/66596.html (Note: While EN standards are European, their principles are widely recognized globally.)

- Understanding Polymer Coatings for Industrial Gloves: A Material Science Perspective. Journal of Protective Equipment Engineering, Vol. 15, Issue 2, 2023. (Fictional academic journal citation for illustrative purposes)

- Advanced Waterproofing Techniques in PPE Manufacturing. Discussion on Industrial Safety & Hygiene Forum, 2022. (Fictional forum citation for illustrative purposes)